| |

| Intro |

| Geomofhological |

| Hidraulic Engineering |

| Industrial Engineering |

| Heritage |

| Civil Engineering |

| Accidents And Claims Aplications |

| INDUSTRIAL ENGINEERING |

APLICATIONS: (See video, phases of the work process))

FHASES OF THE WORK PROCESS INDUSTRY:

1- Scene for rehabilitaton industry facilities.

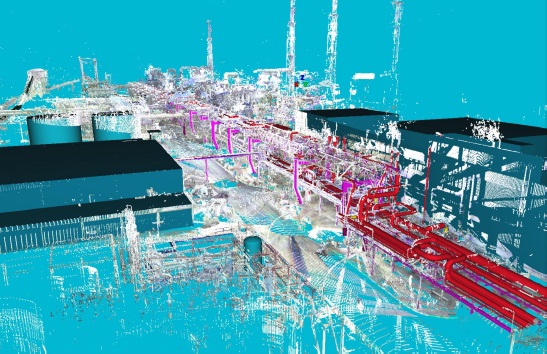

2- 3D Scan Data. Draw existing facilities.

3- Proyect with new facilities adapted to old industry facilities.

|

BENEFITS:

- Planing

- - Planning time lower rate of re-Works.

- - Very quickly in the data capture in the field.

- - Less downtime of plant.

- - Immediate availability of data in the integrable TI of the project.

- Quality

- Quality more accurately than with traditional methods.

- High level of detail.

- Analysis of interference with 3D models (PDS, AutoCAD, MicroStation).

- Mayor calidad documental (As-found/As-built) objetivos, documentos de base para petición de ofertas, proyecto, planificación de montajes-desmontajes, trazabilidad, etc.

- Segurity

- Minimize interferences with manufactures, require no directo contacts with machines, accurate measurement of inaccessible elements. Without scaffolding ,....

- Virtual simulation of mount.

- Costs

- Low access costs and very quickly.

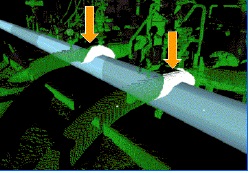

Analysis of interferences

Raw Data, 3D Scan of the Photo. Left image.

As found for new design of elements or old impaired elements for replacement.

Simulacion of mount. All facilities of a ship.

Oil Platform. Facilities.